What are the benefits of Physical Asset Management for critical manufacturing industries?

What is the difference between Operations & Maintenance [O&M] and a total Physical Asset Management strategy?

Do you know how to integrate automation processes to optimise performance?

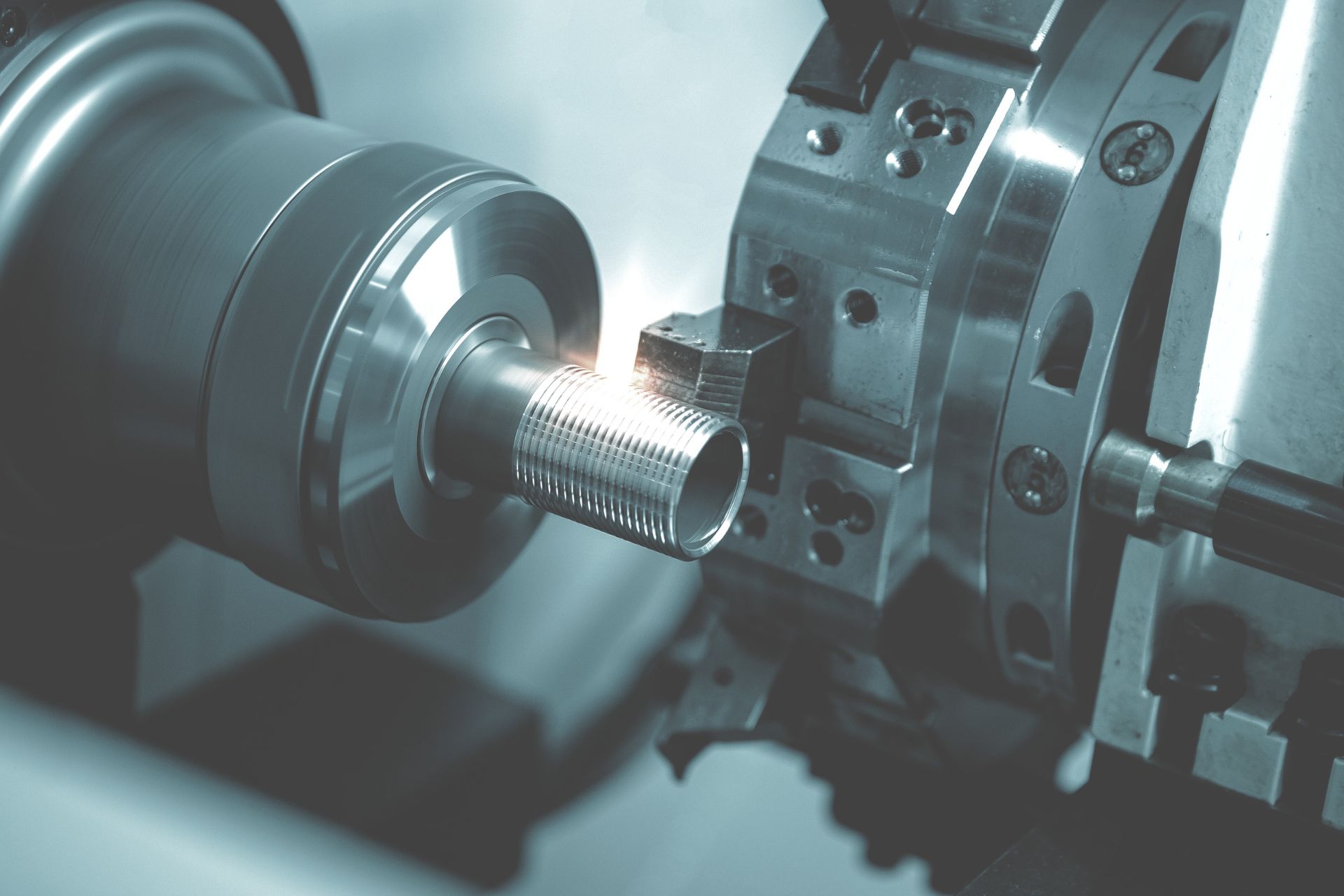

Asset management for the manufacturing industries encompasses the entire lifecycle of plant assets, including equipment, components, production lines, and the buildings themselves. It involves making decisions regarding investment policies and disinvestment strategies. The goal of asset management is to maximize value from physical assets, making Physical Asset Management (PAM) a critical step toward operational excellence and Overall Equipment Effectiveness (OEE). Due to its inherent complexity, asset management in this market is often one of the last avenues explored for maximizing cost savings in a competitive global economy. However, it is a building block of a successful strategy that Atom Group’s team of experts, scientists and technicians with specialist training and years of experience can help you with.

Discover our list of services designed to meet the unique needs of your sector and tailored to your assets. By combining innovative solutions with proven methods, our services deliver tangible results. Indicatively:

Stay updated with a range of news, insights, and technological developments addressing the key issues of today and tomorrow in physical asset management.